Share this

A New Age of Timber: Why the Future is (Lab-Grown) Wood

by Sean Hill on May 22, 2025

In a quiet lab in Kyoto, a group of scientists are shaping the future – and they're doing it with wood.

But not the kind you'd expect.

This isn’t the timber you chop down or the kind you sand and stain. It’s engineered. Reimagined. Built from the smallest building blocks of nature and strengthened through ingenuity. And it just might be one of the most exciting materials for architecture, design, and construction in decades.

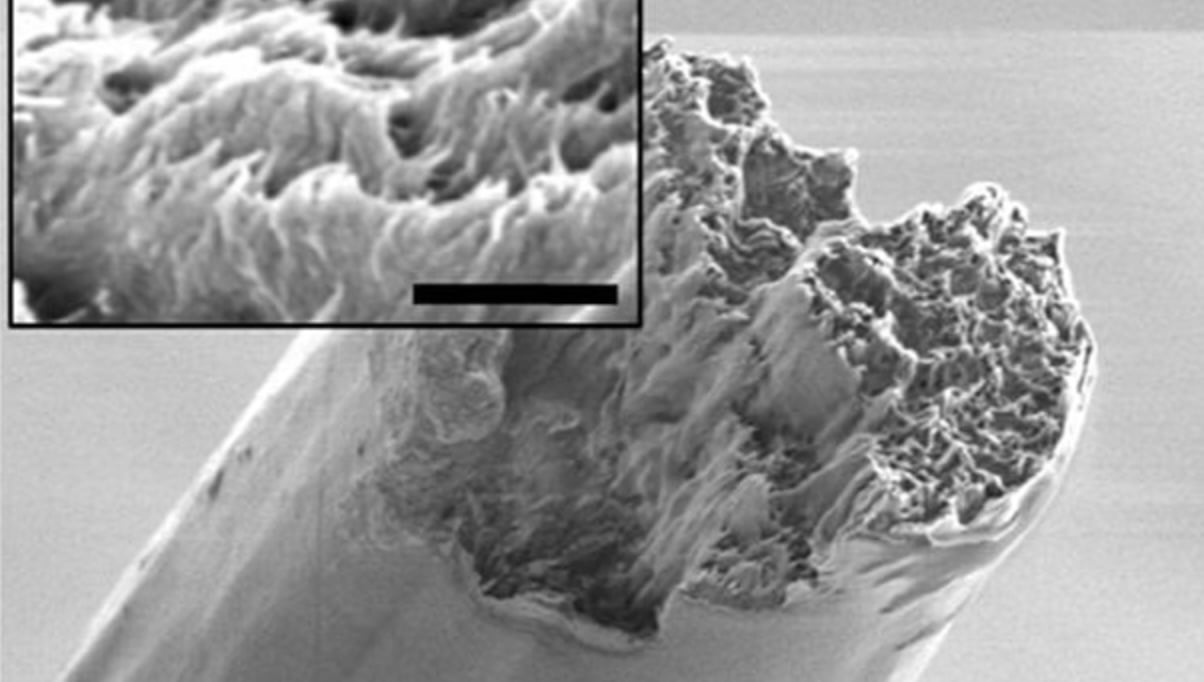

Cellulose nanofibre material under microscope: nature’s answer to steel in the race toward sustainable, lightweight architecture. Image: KTH Royal Institute of Technology.

☉

Stronger Than Steel, Lighter Than Imagination

At the heart of this transformation is the cellulose nanofibre (CNF). Extracted from waste like wood pulp or straw, these plant-based fibers are broken down to the nanoscale and then reassembled into something extraordinary: a material five times stronger than steel by weight, and 80% lighter.

This is not about nostalgia for wooden planes or quaint cabins. It’s about a new class of material with radical performance potential.

One that could eventually replace metal in everything from cars to furniture – even buildings.

☉

Why This Matters to Us

At RISE Design Studio, we’re always looking for materials that don’t just perform, but transform – our buildings, our industry, and our relationship with the planet. CNFs are made from biomass that sequesters carbon. They’re renewable, biodegradable, and produced through low-energy processes.

It’s the kind of material that asks not just what if, but why not?

→ Why not challenge the carbon-heavy status quo of steel and aluminium?

→ Why not build bridges and buildings that give back more than they take?

→ Why not think lighter, stronger, and smarter?

☉

What We’re Learning from Japan

In collaboration with car manufacturers, researchers in Japan are testing these nanofibres in auto parts. Why? Because electric vehicles rely on heavy batteries, and weight is a limiting factor. Lighter structures mean longer ranges, fewer batteries, and less environmental cost. The same logic applies to buildings.

Lighter materials don’t just reduce embodied carbon - they open doors to faster, more adaptable construction. If you're designing a retrofit in a tight urban site or assembling off-site components in a modular housing scheme, weight matters. Every kilogram counts.

☉

The Art of Densifying Nature

At Sweden’s KTH Royal Institute of Technology, another breakthrough: a way to ‘densify’ wood fibres into a structure stiffer than spider silk - previously considered nature’s strongest. By aligning the nanofibres and compacting them into solid form, they’ve created a material that could rival even carbon composites.

But unlike carbon fibre, CNF doesn’t need petrochemicals. It comes from nature, returns to nature, and performs with brilliance in between.

☉

A Material With Legacy

It reminds us of something we often say when working with heritage buildings: the old ways still have something to teach us. But it’s what we do with that wisdom today that defines tomorrow.

There’s poetry in the fact that the material of the future comes from the forests of the past. And that through human creativity, we can push that raw material to perform like never before - for aircraft, for architecture, for generations to come.

☉

Beyond the Lab, Into the Studio

The commercial application is still emerging. The costs are high. The supply chains aren’t built yet. But then again, every breakthrough starts as a question mark.

At RISE, we don’t just follow trends - we study the horizon. We get excited by innovations that align with our values: low carbon, high integrity, beautiful in spirit and form. Whether it’s repurposing brick in a retrofit or trialling future-forward composites in a pavilion, we’re always testing how architecture can do more with less.

The goal is not just to reduce. It’s to reimagine.

☉

From Forest Floor to Skyline

This new super wood isn’t a gimmick. It’s a story about what happens when science, sustainability, and design ambition collide.

We believe that the next generation of architecture will be written not in concrete and glass, but in materials that work with nature, not against it.

Cellulose nanofibre might still be in its infancy, but like all great ideas, it’s rooted in possibility.

☉

Building materials are changing. Are we ready to build a different future?

→ Let’s start the conversation: architects@risedesignstudio.co.uk

→ Or call the studio on 020 3947 5886

RISE Design Studio: Architects, Interior Designers and Sustainability Experts

Company Reg No: 08129708 – VAT No: GB158316403

© RISE Design Studio. Trading since 2011.

Share this

- Sustainable architecture (152)

- Architecture (151)

- Passivhaus (68)

- Design (67)

- Sustainable Design (65)

- Retrofit (59)

- London (51)

- New build (51)

- Renovation (43)

- energy (39)

- interior design (37)

- Building materials (35)

- Planning (34)

- Environment (31)

- climate-change (30)

- Inspirational architects (27)

- Refurbishment (27)

- enerphit (27)

- extensions (27)

- Building elements (22)

- Inspiration (21)

- low energy home (19)

- Rise Projects (16)

- Extension (15)

- Innovative Architecture (14)

- London Architecture (14)

- Sustainable Architect (14)

- net zero (14)

- Carbon Zero Homes (13)

- General (12)

- Philosophy (12)

- sustainable materials (12)

- RIBA (11)

- Working with an architect (11)

- architects (10)

- Awards (9)

- Planning permission (9)

- Sustainable (9)

- Residential architecture (8)

- Sustainable Tennis Pavilion (8)

- architect (8)

- low carbon (8)

- Airtightness (6)

- BIM (6)

- Eenergy efficiency (6)

- Overheating (6)

- Passive house (6)

- Tennis Pavilion (6)

- Uncategorized (6)

- Virtual Reality (6)

- BIMx (5)

- Backland Development (5)

- Basement Extensions (5)

- Carbon Positive Buildings (5)

- Costs (5)

- RISE Sketchbook Chronicles (5)

- cinema design (5)

- construction (5)

- insulation (5)

- local materials (5)

- sustainable building (5)

- AECB (4)

- ARB (4)

- Feasibility Study (4)

- Home extensions (4)

- House cost (4)

- Paragraph 84 (4)

- concrete (4)

- constructioncosts (4)

- modular architecture (4)

- mvhr (4)

- natural materials (4)

- structural (4)

- structuralengineer (4)

- working from home (4)

- Artificial Intelligence (AI) (3)

- Brutalist Architecture (3)

- Building in the Green Belt (3)

- Chartered architect (3)

- Fees (3)

- Home improvement (3)

- Paragraph 79 (3)

- Paragraph 80 (3)

- Permitted development (3)

- Property (3)

- Social housing (3)

- Spain (3)

- Sustainable Architect London (3)

- Sustainable Extensions (3)

- Sustainable Interiors (3)

- Timber Structures (3)

- backland (3)

- building regulations (3)

- circular economy (3)

- country house (3)

- countryside (3)

- furniture (3)

- listed buildings (3)

- plywood (3)

- sustainability (3)

- sustainable structure (3)

- zero waste (3)

- 3D models (2)

- Architects in Spain (2)

- BREEAM (2)

- Bespoke lighting (2)

- Biophilic Design (2)

- Bricks (2)

- Building energy (2)

- CLT (2)

- Chartered Practice (2)

- Clay Plaster (2)

- Commercial Architecture (2)

- Contractor (2)

- Covid-19 (2)

- Designing with Stone (2)

- Ecohouse (2)

- Furniture design (2)

- Garden studio (2)

- Heat Pumps (2)

- Heritage (2)

- Japanese Archiecture (2)

- Kensal Rise (2)

- Loft conversion (2)

- Low Carbon Future (2)

- Mews House Retrofit (2)

- Modern Methods of Construction (2)

- Notting Hill Architects (2)

- Period Homes (2)

- Permitted development rights (2)

- Queen's Park Sustainable Architect (2)

- Recycling (2)

- Roof extension (2)

- Social Distancing (2)

- Store Design (2)

- Sustainable Affordable Homes (2)

- Sustainable Architect Fees (2)

- Sustainable Natural Materials (2)

- Timber Construction (2)

- Welbeing (2)

- West London Architect (2)

- Winter Performance (2)

- ashp (2)

- barcelona (2)

- building information modelling (2)

- co-working (2)

- design&build (2)

- epc (2)

- glazed-extensions (2)

- green architecture (2)

- greenbelt (2)

- health and wellbeing (2)

- historic architecture (2)

- house extension (2)

- interiorfinishes (2)

- light (2)

- living space (2)

- london landmarks (2)

- londoncinemas (2)

- openingupworks (2)

- peter zumthor (2)

- project management (2)

- rammed earth (2)

- renewable energy (2)

- self build (2)

- traditional (2)

- trialpits (2)

- waste (2)

- wooden furniture (2)

- #NLANetZero (1)

- 3D Printing (1)

- 3D Walkthroughs (1)

- Adobe (1)

- Agriculture and Architecture (1)

- Alvar (1)

- Architect Barcelona (1)

- Architecture Interior Design (1)

- Architraves (1)

- Area (1)

- Art (1)

- Audio Visual (1)

- Balconies (1)

- Biodiversity (1)

- Biophilic Architecture (1)

- Birmingham Selfridges (1)

- Boat building (1)

- Boats (1)

- Brass (1)

- Brent Planning (1)

- Brexit (1)

- Brownfield Development (1)

- Carpentry (1)

- Casting (1)

- Chailey Brick (1)

- Cold Water Swimming (1)

- Community Architecture (1)

- Concrete Architecture (1)

- Construction Costs (1)

- Copper (1)

- Cornices (1)

- Corten (1)

- Cowboy Builders (1)

- Czech Republic, (1)

- Data Centers (1)

- David Hockney (1)

- David Lea (1)

- Digital Twin (1)

- Domus Nova (1)

- Dormer extension (1)

- Embodied Carbon (1)

- EnvironmentalArchitecture (1)

- Flooding (1)

- Future of Housing (1)

- Gandhi memorial museum (1)

- Georgian Extension (1)

- Green Register (1)

- Green infrastructure (1)

- GreenDesign (1)

- History (1)

- India (1)

- Interior Finishes (1)

- Jan Kaplický (1)

- Japandi (1)

- Joinery (1)

- Kitchen Design (1)

- L-shaped dormer (1)

- Land value (1)

- Leonardo Da Vinci (1)

- Lord's Media Centre (1)

- Mapping (1)

- Marseilles (1)

- Mary Portas (1)

- Metal (1)

- Micro Generation (1)

- Mid Century Retrofit (1)

- Monuments (1)

- Mouldings (1)

- Museum Architecture (1)

- Mycelium Architecture (1)

- NPPF (1)

- Nature (1)

- New Build House (1)

- Office to Homes (1)

- Office to Hotel Conversion (1)

- Offsite manufacturing (1)

- Origami (1)

- Padel Court (1)

- Party Wall Surveyor (1)

- PeopleFirstDesign (1)

- Place (1)

- Podcast (1)

- Porch (1)

- Prefab (1)

- Procurement (1)

- Public Housing (1)

- Queen's Park (1)

- RISE Team (1)

- Rebuild (1)

- Replacement Dwelling (1)

- ResilientFuture (1)

- Richard Rogers (1)

- Rural New Build (1)

- Sand (1)

- Scandinavian architecture (1)

- Selfbuild (1)

- Skirting (1)

- Slow Architecture (1)

- Small Sites Development (1)

- Solar Shading (1)

- Steel (1)

- Stone Architecture (1)

- Surveying (1)

- Sustainable Basement Extension (1)

- Sustainable Building Systems (1)

- Sustainable Housing (1)

- Sustainable Lighting (1)

- Sustainable Mews House (1)

- Sustainable Padel Court (1)

- Sustainable Retail Store (1)

- Sverre fehn (1)

- UFH (1)

- VR (1)

- Victorian Extension (1)

- Walkable Cities (1)

- West london (1)

- Whole Life Carbon (1)

- Wildlife (1)

- Wood (1)

- architect fees (1)

- architectural details (1)

- arne jacobsen (1)

- avant garde (1)

- basements (1)

- brentdesignawards (1)

- building design (1)

- built environment (1)

- carbonpositive (1)

- cement (1)

- charles correa (1)

- charles eames (1)

- charlie warde (1)

- charteredarchitect (1)

- climate (1)

- climate action (1)

- codes of practice (1)

- collaboration (1)

- covid (1)

- dezeenawards (1)

- drone (1)

- eco-living (1)

- emissions (1)

- finnish architecture (1)

- foundations (1)

- futuristic (1)

- georgian architecture (1)

- glazed envelope (1)

- good working relationships (1)

- green building (1)

- hampstead (1)

- happiness (1)

- home extension (1)

- homesurveys (1)

- imperfection (1)

- independentcinemas (1)

- innovation (1)

- inspirational (1)

- internal windows (1)

- jean prouve (1)

- kindness economy (1)

- kintsugi (1)

- landscape architecture (1)

- lime (1)

- local (1)

- lockdown (1)

- mansard (1)

- manufacturing (1)

- materiality (1)

- modern architecture (1)

- moderninst (1)

- modernism (1)

- moulded furniture (1)

- natural (1)

- natural cooling (1)

- natural light (1)

- nordic pavilion (1)

- northern ireland (1)

- palazzo (1)

- placemaking (1)

- planningpermission (1)

- plywood kitchen (1)

- post-Covid (1)

- poverty (1)

- powerhouse (1)

- preapp (1)

- preapplication (1)

- ray eames (1)

- reclaimed bricks (1)

- recycle (1)

- reuse (1)

- ricardo bofill (1)

- risedesignstudio (1)

- rooflights (1)

- room reconfiguration (1)

- rural (1)

- satellite imagery (1)

- selfbuildhouse (1)

- shared spaces (1)

- site-progress (1)

- solarpvs (1)

- space (1)

- stone (1)

- structuralsurvey (1)

- sun tunnel (1)

- terraces (1)

- thegreenregister (1)

- totality (1)

- wabi-sabi (1)

- January 2026 (3)

- December 2025 (10)

- November 2025 (14)

- October 2025 (9)

- September 2025 (10)

- August 2025 (13)

- July 2025 (23)

- June 2025 (10)

- May 2025 (22)

- April 2025 (16)

- March 2025 (8)

- February 2025 (12)

- January 2025 (6)

- December 2024 (6)

- November 2024 (8)

- October 2024 (5)

- September 2024 (3)

- August 2024 (2)

- July 2024 (2)

- June 2024 (2)

- May 2024 (1)

- April 2024 (1)

- March 2024 (1)

- February 2024 (1)

- January 2024 (3)

- November 2023 (1)

- October 2023 (5)

- September 2023 (7)

- August 2023 (7)

- July 2023 (6)

- June 2023 (8)

- May 2023 (14)

- April 2023 (11)

- March 2023 (8)

- February 2023 (6)

- January 2023 (5)

- December 2022 (3)

- November 2022 (3)

- October 2022 (3)

- September 2022 (3)

- July 2022 (2)

- June 2022 (1)

- May 2022 (1)

- April 2022 (1)

- March 2022 (1)

- February 2022 (2)

- January 2022 (1)

- November 2021 (1)

- October 2021 (2)

- July 2021 (1)

- June 2021 (1)

- May 2021 (1)

- April 2021 (1)

- March 2021 (1)

- February 2021 (1)

- January 2021 (2)

- December 2020 (1)

- November 2020 (1)

- October 2020 (1)

- September 2020 (2)

- August 2020 (1)

- June 2020 (3)

- April 2020 (3)

- March 2020 (2)

- February 2020 (3)

- January 2020 (1)

- December 2019 (1)

- November 2019 (2)

- September 2019 (1)

- June 2019 (1)

- April 2019 (2)

- January 2019 (2)

- October 2018 (1)

- September 2018 (1)

- August 2018 (2)

- July 2018 (1)

- March 2018 (1)

- February 2018 (2)

- December 2017 (1)

- September 2017 (1)

- May 2017 (1)

- January 2017 (1)

- December 2016 (1)

- November 2016 (1)

- September 2016 (1)

- August 2016 (2)

- June 2016 (2)

- May 2016 (1)

- April 2016 (1)

- December 2015 (1)

- October 2015 (1)

- September 2015 (1)

- August 2015 (1)

- June 2015 (1)

- January 2015 (1)

- September 2014 (2)

- August 2014 (1)

- July 2014 (4)

- June 2014 (9)

- May 2014 (2)

- April 2014 (1)

- March 2014 (1)

- February 2014 (1)

- December 2013 (1)

- November 2013 (5)

- October 2013 (5)

- September 2013 (5)

- August 2013 (5)

- July 2013 (5)

- June 2013 (2)

- May 2013 (2)

- April 2013 (4)

- March 2013 (5)

- February 2013 (2)

- January 2013 (3)